Sustainability

Circular economy and sustainable packaging

In the world of packaging there is a significant move toward more sustainable packaging to prevent packaging waste finishing up in the oceans and in landfill [1].

Packaging in itself is however essential because it keeps your product fresh, protects it and enables it to be transported. Did you know that a product with too little packaging has a greater environmental impact than a product with more packaging [2]?

Using packaging is therefore important, but how can we prevent its wastage and make it more sustainable? The question is clear, the answer more nuanced.

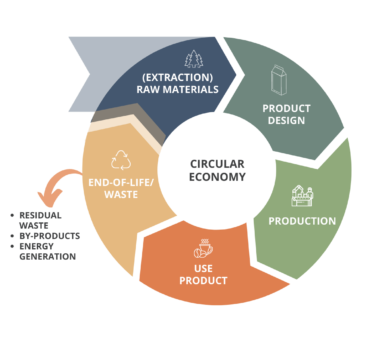

Circular economy

We have adopted the model of the “circular economy”. The principle behind this is to convert today’s waste into tomorrow’s raw materials. The principle is not simply that waste substances can be brought back into the circuit, for example by recycling or composting, but that the ecological footprint can be kept as low as possible at all stages of the process: from optimal product design and efficient production through to use and end-of-life of a product.

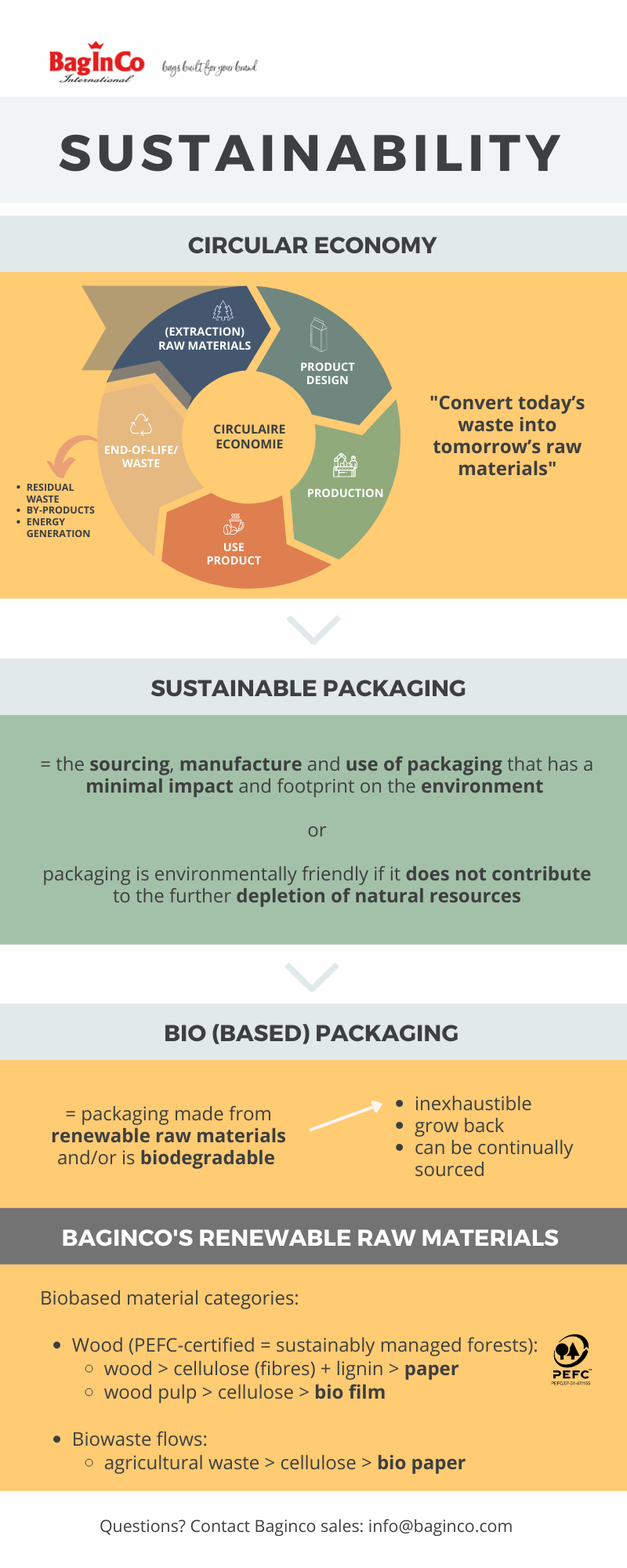

Sustainable packaging

If we apply this to the world of packaging, this amounts to a move to “sustainable packaging”. But what does this mean in practice?

Sustainable packaging is the “sourcing”, manufacture and use of packaging that has a minimal impact and footprint on the environment [3]. Or packaging is environmentally friendly if it does not contribute to the further depletion of natural resources.

In other words, in the light of the circular economy and sustainable packaging, environmental benefits can be achieved in various ways. They can be achieved, for example, by adapting the packaging to the product, by optimising logistics, by consuming less energy during production, by recyclability or the use of renewable resources [4].

Bio (based) packaging

A step further in sustainable packaging is possible in selecting bio (based) packaging. Biopackaging is made from renewable raw materials and/or is biodegradable [5].

Renewable raw materials are inexhaustible, grow back and can be continually sourced [6]. This is environmentally friendly in the sense that it does not contribute to the depletion of natural resources.

There are various categories of renewable raw materials. At Baginco we opt for the use of wood and bio-residues.

The one we have been working with the longest is wood. Paper is made from the by-product which we naturally use for our packaging.

References are also made to vegetable renewable materials. This includes wood and bamboo, but can also include for example corn, cane sugar, potatoes etc. However, at Baginco, we have decided not to use the latter, since these are raw materials which are intended for food production and we do not wish to promote their use for packaging.

Biowaste flows is another category. This is the waste left over once all of the reusable or recyclable waste has been removed from the main flow.

An example of this is paper that is made from the residual waste from agriculture. Read more about this under “Raw materials”.

Summary

At Baginco we try to innovate and provide a solution to our customers during every step in the process, from raw materials to waste. We are however in a changing world and we must take the current context into account. The following explains every step in the process. Go to:

Footnotes:

[1] https://www.mckinsey.com/industries/paper-forest-products-and-packaging/our-insights/the-drive-toward-sustainability-in-packaging-beyond-the-quick-wins#

[2] Indufed Brochure: Glass and paper – Pioneers of the circular economy

[3] https://www.bigcommerce.com/blog/sustainable-packaging/#what-is-sustainable-packaging

[4] http://www.preventpack.be/nl/dossier/bioverpakkingen

https://mooimakers.be/kenniswijzer/artikel/duurzaam-verpakken

[5] http://www.preventpack.be/nl/dossier/bioverpakkingen

[6] https://www.pianoo.nl/nl/themas/maatschappelijk-verantwoord-inkopen/mvi-themas/biobased-inkopen/toelichting/wat-zijn