Sustainability: recyclability of paper bags

What follows is background information on the recyclability of paper, bio paper/bio film and PP film. The sorting directives for each country will then explained.

Recyclability of paper

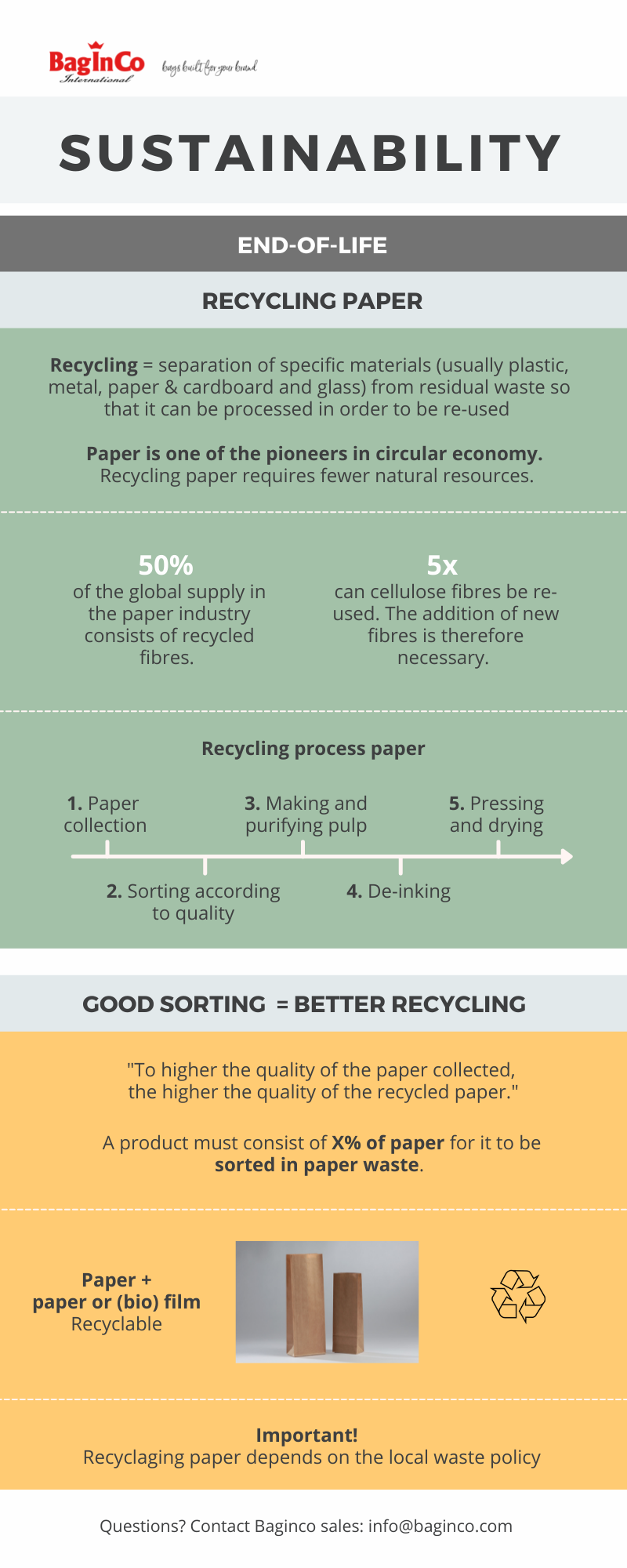

First and foremost, what does recycling mean? Recycling is the separation of specific materials (usually plastic, metal, paper & cardboard and glass) from residual waste so that it can be processed in order to be re-used [1].

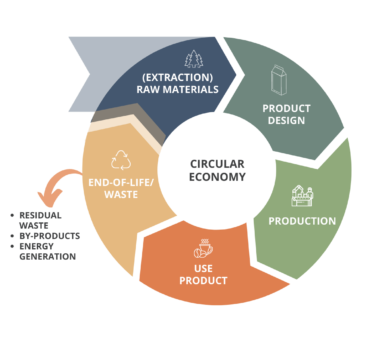

Paper is one of the pioneers in the field of recycling and a model for the circular economy [2].

The cellulose fibres, originating from wood and from which paper is made, can be re-used up to 5 times to be made into new paper. The addition of new fibres is therefore necessary to keep the cycle in progress.

Did you know that 50% of the global supply in the paper industry consists of recycled fibres [3]?

The proper sorting of paper is essential to keep the recycling process pure and to be able to continue to generate good quality paper. Paper that is damp or greasy cannot be properly recycled as moisture and dirt damage the wood fibres.

The recycling process runs largely according to these steps:

- Paper collection

- Sorting according to quality

- Making and purifying pulp

- De-inking

- Pressing and drying

For more information about the paper recycling process, please go to Fostplus (Belgium)[4] or Paprec (France)[5].

Recyclability of bio paper and bio film

The main component of bio paper and bio film is cellulose fibres, from which paper is also made. However, there is no guarantee of an effective recycling process. Recycled paper is made from pulp [6]. However, bio film is known to be non-pulpable [7].

For bio paper, a recyclability test has been conducted by WEPA, the conclusion of which is that bio paper from PaperWise is pulpable [8]. At the moment however, we do not have sufficient information to assess the effect of PaperWise paper on the recycling process and the quality of the recycled paper.

Recyclability of film

Film, polypropylene or metallised, is plastic and therefore recyclable. Recycling of plastic is important as it reduces the need to use natural resources to make new plastic.

The recycling process for plastic runs largely according to these steps:

- Plastic collection

- Sorting using advanced technology

- Washing and crushing

- Processing

For more information about the film recycling process, please go to Fostplus (Belgium)[9] or Paprec (France)[10].

Sorting guidelines for paper bags

Sorting packaging waste and collecting it separately is important to the recycling process for paper. In general, a product must consist of X% of paper for it to be sorted in paper waste. This percentage differs from country to country. Here is a summary:

Belgium

In Belgium, packaging must consist of at least 85% paper for it to be sorted with paper so it can be recycled [11]. That is to say:

- > 85% paper, sort with paper

- < 85% paper, sort with residual waste or separate film from paper and sort separately

For all questions surrounding sorting and recycling in Belgium, please contact FostPlus [12].

France

In France, packaging must consist of at least 50% paper for it to be sorted with paper so it can be recycled [13].

- > 50% paper, sort with paper (collection point or bin with a yellow lid)

For all questions surrounding sorting and recycling in France please contact Citeo [14].

For all information on logos, please see the presentation by Adelphe.

Netherlands

In the Netherlands, packaging must consist of at least 100% paper for it to be sorted with paper so it can be recycled. This rule of thumb applies in the Netherlands: if you can tear the paper, it can go in with paper[15]. That is to say:

- 100% paper, sort with paper

- < 100% paper, sort with residual waste or separate film from paper and sort separately

For all questions surrounding sorting and recycling please contact Milieu Centraal [16].

Footnotes:

[1] The glossary of sustainability

[2] https://www.papier.be/nl/mythes-en-feiten/recyclage/

[3] https://www.paprec.com/en/our-vision/our-vision-for-the-future/

[4] https://www.fostplus.be/nl/recycleren/papier-karton

[5] https://www.paprec.com/fr/comprendre-le-recyclage/le-recyclage-en-infographie/

[6] https://www.indufed.be/nl/papier-karton-glas/papier-kartonproductie/

[7] https://www.natureflex.com/faq/

[8] PaperWise recyclability report by Wepa 20200609

[9] https://www.fostplus.be/nl/recycleren/plastic-verpakkingen

[10] https://www.valorplast.com/comment-recycler-le-plastique/comment-fonctionne-le-recyclage-plastique/les-grandes-etapes-du-recyclage-plastique

[11] https://www.pack4recycling.be/nl/content/papier-karton-verpakkingen-met-meer-dan-85-papier

[12] https://www.fostplus.be/nl/sorteren-recycleren/sorteerregels-papier-karton

[13] https://www.adelphe.fr/sites/default/files/documentation/201909_guide_info-tri_adelphe_0.pdf

https://www.triercestdonner.fr/

[15] https://www.afvalscheidingswijzer.nl/categorieen/papier-en-karton/

[16] https://www.milieucentraal.nl/minder-afval/afval-scheiden/papier-en-karton/