Sustainability: raw materials

Our bags consist of 2 parts: an outer and an inner finish.

Outer finish

Paper

We are in the business of paper packaging because we believe in the strengths of paper. It is one of the oldest, most sustainable raw materials that is rewarding to work with in packaging.

Paper is made from wood, which contains fibres (cellulose) and binding agent (lignin). These are recyclable and can therefore be returned to the circuit. Read more about this under “Recycling”.

By the way, did you know that the paper we use is PEFC certified [1]? This means that it comes from sustainably managed forests. It therefore contributes positively to the preservation of forests and not to their disappearance, as is sometimes thought [2].

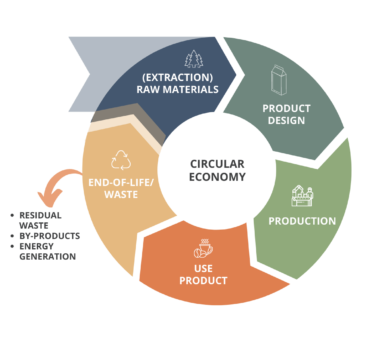

The paper industry is a driving force behind ensuring that forests are protected and even grow so that we can continue to use renewable resources [3]. This is the main point of the circular economy.

Bio paper

There are various alternatives on the market which are similar to paper but which originate from other sources, also referred to as biobased products. The difference, in theory, is that they are compostable. This is a different, newer arena in waste policy. Read more about this under “Composting”.

In this category of bio paper, we work with the paper from Paperwise. Paper from Paperwise is made from agricultural waste that would otherwise be burnt. Agricultural waste, also referred to as agricultural residues, are used to extract cellulose, which is the major component in paper [4].

Inner finish

For the inner finish, there is a choice between (greaseproof) paper, film (PP or metallised) or a bio film.

Film

The film is made of polypropylene (PP), which is a thermoplastic polymer that consists of non-toxic molecules (carbon and hydrogen atoms) [5]. As this is a conventional polymer that is not biologically degradable and originates from petrochemical raw materials, this does not come under the category of renewable raw materials.

There is currently greater demand for petroleum than can be produced naturally. As a result, this is a raw material which we must use prudently. In the current mindset, plastic is often depicted as “bad”, which is an over-simplification.

In addition to the reduction of plastic consumption, recycling it is one of the best solutions. Read more about the recyclability of plastic under “Recycling”. Recycling can contribute to the circular economy. To find out more about the circularity of plastics, please read the Central Planning Bureau’s Background Document [6].

It is also important to note that only 4% to 8% of the demand for petroleum and gas is used for plastics (of which approximately half as raw materials and the other half as fuel). In this sense, the PP film is a by-product of the fuel and energy function of petroleum and gas.

The main reason for opting for a PP film is because it provides one of the best barriers against air, moisture and grease seepage. This ensures that the product that you pack has a longer shelf life, which therefore helps to avoid food wastage.

Bio film

The other option we offer is a bio film, which is made from 90% renewable raw materials. This is the highest percentage on the market! The raw material is cellulose which is extracted from wood pulp. Just like our paper, this originates from PEFC certified forests [7].

Just like the PP film, the bio film forms a barrier against air, moisture and grease seepage. Please note though, the bio film is thinner (23µ) than the PP film (30µ). It has similar properties, but it is not the same.

It is important to note that the bio film is, in theory, compostable but not recyclable. Read more about this under “Composting”.

Footnotes:

[1] https://www.baginco.com/nl/stories/pefc-certificaat-jouw-garantie-voor-een-duurzaam-bosbeheer/

[2] https://www.papier.be/nl/mythes-en-feiten/bos/

[3] https://www.upm.com/responsibility/forests/

[4] https://paperwise.eu/milieuvoordeel-2/

[5] https://www.ti-films.com/en/sustainability/environmental-report

[6] CPB Background Document: The circular economy of plastic